McCoy Torque Turn System – MTT™

FOR BUCKING AND MAKE/BREAK UNITS

Leading-Edge Solutions for Optimal Performance

McCoy Global is transforming the industry with innovative technology solutions that enable our customers’ success, delivering optimal operational efficiency and performance, while keeping people, assets and the environment safe.

Innovation

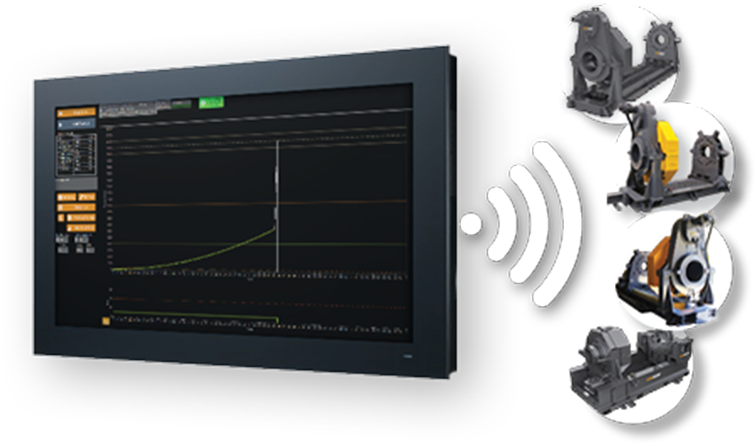

Innovative system and software specifically designed for use with Bucking units and Make/Break units.

Expertise

20+ years of experience with thousands of torque monitoring systems in the field supporting customers’ needs.

Versatility

Works with McCoy Bucking units and Bucking units from other manufacturers.

Applications

- Torque Turn system specifically designed for use with Bucking and Make/Break units

- Monitor, control and analyze tubular connections make-up to ensure that all tubing and casing connections conform to manufacturer specifications

- MTT system monitors torque, turns and rotation speed of any Bucking and Make/Break unit in real-time

The system uses MTT software that interacts with external control hardware and allows user to easily specify make-up parameters, control the process and evaluate quality of each connection make-up. Standard software features provide torque/turn graphs, generate customized reports and offer the ability to review results from previous make-ups for further analysis and information.

MTT System Components

MTT-4100-6860-0000-0004-00-CE

MTT System hardware comes standard with:

- Display + Keyboard + Ethernet Cable

- MTT Controller Unit

- Encoder

- Cables included are encoder, ethernet and power cables

Features and Benefits

VTR Compatible

MTT software can support Virtual Thread Rep™ technology.

Technical Support

24/7 Technical Support is available as well as on site support.

Software Upgrades

Free MTT Software Updates are available on the VTR portal or by contacting McCoy Service Department.

Hardware Features and Benefits

- Large 21-inch industrial display with a mounting arm for easy operation

- Controller with individual connections for easy direct sensor connections

- Controller and PCs are separate to overcome the short lifecycle of PCs allowing the System to be in service much longer

- Improvement in Architecture: flexible sensor configuration, wired or wireless ethernet communication, control electronics separate from computer housing

- Multiple sensor inputs allow for torque averaging / make / break operation from the same controller. No separate junction box needed.

- Sensor/Cable Open Fault Detection, Output Short Protection

- Works with McCoy Bucking Units and bucking units from other manufacturers

Software Features and Benefits

Standard

- Easy graphical report creation and “one step” PDF reporting system with customizable logo

- Automatic descriptive comments with user override

- Multiple joints review, graphic overlay

- Graph zooms to maximize size to computer screen

- Connection library – User customizable

- Automatic “Start Recording” and “Dump Valve Release”

- Adjustable Color Scheme

- Shoulder slope calculation

- User Mode - Administration and User Level 1 & 2 Access

Optional

Specialized

- Customizable components available on request

- Accept or reject connection on delta turn / shoulder slope

- RPM Graph can be added \to make-up screen

- Custom zoom feature

- Pressure test system

Controller and System Specifications

Controller and System Specifications

- Sampling Rate: Base Rate 500 Samples/Second

- Torque Accuracy: Typically <0.5% Full Scale (not including Load Cell)

- Turns Accuracy: +/- 1 pulse of turns counter

- RPM Accuracy: Better than 0.25 RPM Error

- Pressure Accuracy: Typically <1%

- Response Time: Electronic Dump Valve Output Control:< 0.5 ms

- Hydraulic dump valve: typical 10 to 30 ms

- Approvals: iec 61010 – safety evaluated ce/lvd/emc/rohs/fcc.emc

- Power requirement: 100-240 V~, 50-60 Hz

- Power consumption: 1.4a max @ 100V~, 0.87a max @240V~

- Fcc - emc

- Rated temperature: -30°C +50°C, -22°F +122°F

- Altitude: 3048m

- Maximum humidity: 95% – non-condensing

- Protection: Nema 4, ip65

- Communication options: Wi-Fi 802.11 b/g or Bluetooth LE, ethernet 10/100

Display Specifications

- 21.5” true-flat Full HD LCD panel with projected capacitive touchscreen

- Anti-glare coating

- Intel® Core™ i5-7300U(default); i7-7600U/i3-7100U (optional) processor with fan-less system design

- Dual Gigabit Ethernet with IEEE1588 support

- Comes with heavy duty VESA Mount

- Windows 10 Operating Temperature 0 ~ 50 °C (32 ~ 122 °F)

Note:

Panel PC is industrial rated but not waterproof.

Adequate steps should be taken to protect the display.

Load Cell Options

Part Number |

Type |

Form Factor |

Description |

|---|---|---|---|

MTT-OPT-470 |

Electronic |

Clevis Pin |

ASSEMBLY, Make Only, 6K |

MTT-OPT-471 |

Electronic |

Clevis Pin |

ASSEMBLY, Make Only, 10K |

MTT-OPT-472 |

Electronic |

Load Pin |

ASSEMBLY, Make Only, 25K |

MTT-OPT-473 |

Electronic |

Load Pin |

ASSEMBLY, Make Only, 25K, SIZE 50 |

MTT-OPT-474 |

Electronic |

Load Cell |

ASSEMBLY, Make Only, 30K, BUTTON COMPRESSION |

MTT-OPT-475 |

Electronic |

Load Pin |

ASSEMBLY, Make Only, 50K |

MTT-OPT-476 |

Electronic |

Load Cell |

ASSEMBLY, Make Only, 20K, PANCAKE (RoHS) |

MTT-OPT-477 |

Electronic |

Load Cell |

ASSEMBLY, Make Only, 30K, PANCAKE (RoHS) |

MTT-OPT-478 |

Electronic |

Load Cell |

ASSEMBLY, Make Only, 50K, PANCAKE (RoHS) |

MTT-OPT-479 |

Electronic |

Clevis Pin |

ASSEMBLY, Make/Break, 6K |

MTT-OPT-480 |

Electronic |

Clevis Pin |

ASSEMBLY, Make/Break, 10K |

MTT-OPT-481 |

Electronic |

Load Pin |

ASSEMBLY, Make/Break, 25K, SIZE 50 |

MTT-OPT-482 |

Electronic |

Load Pin |

ASSEMBLY, Make/Break, 25K |

MTT-OPT-483 |

Electronic |

Load Pin |

ASSEMBLY, Make/Break, 50K |

MTT-OPT-485 |

Electronic |

Load Cell |

ASSEMBLY, Make/Break, 30K, PANCAKE (RoHS) |

MTT-OPT-486 |

Electronic |

Load Cell |

ASSEMBLY, Make/Break, 30K, PANCAKE (RoHS) |

MTT-OPT-487 |

Electronic |

Load Pin |

ASSEMBLY, Make/Break, 50K, PANCAKE (RoHS) |

MTT-OPT-488 |

Electronic |

Load Pin |

ASSEMBLY, 50K, AVERAGING |

Notes:

- Load Cell must be selected separately, since various bucking and make/break unit models require a different type of load cell

- A 30-foot cable is included with each load cell ordered

- Make/Break and Averaging options include 2 load cells and 2 cables

- McCoy offers a large selection of load cell options to choose from (see table above)